I've got one of those fairly standard Flo-Master pump sprayers. I've had the sprayer for quite some time, and even upgraded the sprayer wand to one with a more precise On/Off lever.

Just all of a sudden the sprayer seems to not be able to hold pressure when it's pumped. These piston pumps aren't exactly hydraulic magic, as the piston just draws in air and forces it down the shaft and out the bottom, through the one-way pump check valve gasket, which pressurizes the pump reservoir and causes the liquid material to be forced out through the pick-up tube, and out through the sprayer wand.

The sprayer really has only three points of failure, which is the gasket at the top of the piston pump thread (which screws into the sprayer neck), and the O-ring at the bottom of the piston pump and the piston pump check valve gasket. A close visual inspection of all of those shows them to seemingly be in good working condition.

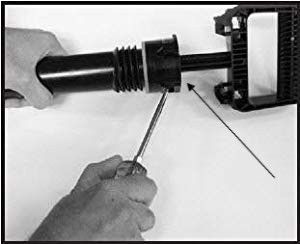

The mystery is the location where I can hear (and feel) the air pressure escaping. It appears to clearly be leaking out of the top of the pump assembly (as the arrow indicates) and where the piston assembly slides into the pump shaft, and where outside is actually drawn into the pump shaft, before the piston forces it down into the sprayer. This is a complete puzzle, because the only way air can be escaping up the pump shaft is if there's a failure in the piston pump check valve gasket AND the piston pump O-ring. Again, both of these appear to be fine. I removed, inspected and cleaned both gaskets and re-seated them and yes, I applied some petroleum jelly to the piston pump O-ring to ensure a good seal. I'm not a big non-fan of just randomly replacing parts, so for that reason I'm totally disinclined just replace the gaskets/O-rings to no purpose.

It just seems like there would have to be a leak/crack in the piston pump shaft assembly somewhere, which is allowing air to pass from the sprayer back into the pump piston shaft, and then back up into the air intake/inlet at the top. This seems logical, since it's the only way that air could bypass the check valve gasket and the O-ring on the pump. But a close visual inspection shows nothing (cracks, etc.) in the shaft assembly, mostly because it's just an extruded high strength plastic - which will last well, forever.

So, yes - this seems like a lot of trouble for what amounts to a $15 pump sprayer, but the fun (for me . . .) is in the diagnostic, and then the fixing. I'm sure it's a character flaw . . . but you can blame it on my dad (he was an engineer), and apparently the nut doesn't fall far from the tree. Any ideas from "the crowd"?